-40%

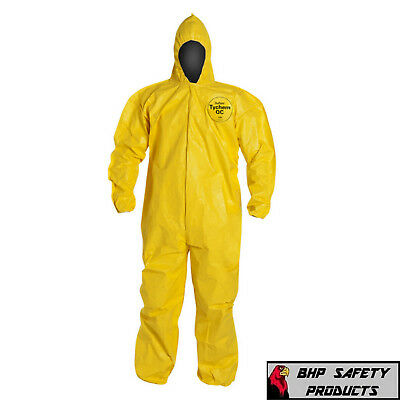

MIRA Safety HAZ-SUIT Protective CBRN HAZMAT Suit

$ 68.11

- Description

- Size Guide

Description

When it comes to serious disasters and hazmat chemical exposure—the MIRA Safety HAZ-SUIT makes NO compromises.Engineered to be one of the most durable, longest-lasting, and most flexible hazmat suit solutions on the market today, the MIRA Safety HAZ-SUIT provides comprehensive protection from a whole universe of CBRN agents and gives you a practical solution for decades to come.

Developed in partnership with Kappler, an international leader in personal protective apparel, the MIRA Safety HAZ-SUIT is one of the world’s

only

disposable hazmat suits offered in a wide variety of sizes—fitting children as young as 4 years old—and it’s available exclusively through MIRA Safety.

Our HAZ-SUIT fabric is made from a durable, puncture-resistant film composite with an excellent barrier to over 125 chemicals including chemical warfare agents (CWA) and toxic industrial chemicals (TIC).

This military hazmat suit is used extensively by major fire departments for hazmat response, major hospitals for emergency preparedness first receivers, major chemical companies for a wide range of potential hazmat exposures, and most branches of the US Military (Department of Defense, DoD).

The fabric of this hazmat suit suit has been subjected to a variety of long-term storage conditions and exhibits no degradation in performance over time when stored properly in a cool, dry place away from direct sunlight. That means it could last for decades or

longer

without compromising on protection.

The MIRA Safety HAZ-SUIT is ideal for demanding hazardous applications with potential for chemical splash, even in significant exposure scenarios. Increased physical strength and even broader chemical holdout take the protection level of this fabric up a serious notch.

With an extensive chemicals-tested list, the MIRA Safety HAZ-SUIT delivers the ultimate in hazmat protection.

Key Features of the MIRA Safety HAZ-SUIT

Comes in youth sizes to fit children as young as 4 years old.

Ideal for CBRN civil defense applications.

Used by professionals all over the world, including the US Military.

Composed of rugged fabric with practically unlimited shelf life (compared to common hazmat suits with a 5-10 year shelf life).

By request, available in NFPA certified styles for bulk orders.

Proudly made in the USA.

Tested & proven protection from a wide variety of CWA & ITC threats (see below for details).

Increased physical/tensile strength and broad chemical holdout for durable, long-lasting protection in the event of a disaster.

Features a heat-sealed and taped stream for ideal protection from particulate and vapor hazards.

Compatible with all MIRA Safety gas masks & full-face respirators.

Offers reliable, long-lasting protection from deadly gases like sarin and VX for up to 8 hours.

Typical Applications: Civil defense, hazmat response, military operations, law enforcement drug response, chemical handling, petrochemical handling and maintenance.

The ONLY Hazmat Suit You’ll Ever Need

Hazmat suits are—unfortunately—one of the most commonly-overlooked aspects of disaster preparation.

Because most people focus on gas masks and full-face respirators, they often overlook the crucial addition of a reliable hazmat suit…or they’ll go with the most basic low-cost alternative on the market. But not all hazmat suits are created equal…

The most common biohazard suits on the market provide limited protection and are intended for use on a job site where users are exposed to a limited range of chemicals and minimal wear-and-tear. Those entry-level suits are mostly designed for a single day’s use in low-impact environments, so they can easily be disposed of and replaced at minimal cost.

But when it comes to preparation, you never know exactly

what

you’ll be facing—a single unexpected puncture to your radiation suit could compromise your health and safety.

That’s why MIRA Safety worked with Kappler to develop a proprietary range of suits that deliver protection above and beyond the common hazmat solution.

Utilizing durable, puncture-resistant fabric (the same as military hazmat suits), we’ve developed a multi-purpose CBRN suit solution that serves as a biohazard suit, radiation protection suit, and chemical suit all in one.

It’s the same durable fabric used in some of the most expensive and elite NBC suits on the market today and trusted in the harshest environments by top professionals.

Our HAZ-SUIT is a Level B hazmat suit available in six sizes to comfortably fit every member of your family or group and provide full-body protection from up to 8 hours of direct exposure to some of the deadliest chemical, radioactive (alpha particles), and toxic agents in the world today.

That’s enough time to get yourself and your party to safety without having to worry about unexpected punctures or dangerous exposure. And with its superior tensile strength, you’ll have added protection from punctures in the case of debris or slip-and-fall accidents.

When stored properly, these suits can be trusted to perform for

decades

without any special maintenance or upkeep (see below).

Our MIRA Safety HAZ-SUIT suit makes no compromises when it comes to protecting you from potentially life-threatening CBRN agents—and you shouldn’t have to make any either.

Remember that in addition to a functioning respirator and HAZ-SUIT, you’ll also need reliable gloves, chemtape, and boots to ensure proper protection from airborne contaminants, radiation, and other CBRN threats.

Size Guide

SIZE

HEIGHT

WEIGHT (LB)

2X/3X

6'2 - 6'5

220-300

LG/XL

5'7 - 6'2

160-220

SM/MD

5'3 - 5'7

120-160

XS

5'0 - 5'3

90-115

YL

4'2 - 5'0

60-90

YS

3'3 - 4'2

35-60

Chemical Warfare Agent Data**

CHEMICAL AGENT

MINUTES

CRITERIA

Bis (2-chloroethyl) sulfide (Mustard:HD)

>480

4.0 ug/cm2

Isopropyl methylfluorophosphonate (Sarin:GB)

>480

1.25 ug/cm2

Chlorovinyl arsinedichloride (Lewisite:L)

>240

4.0 ug/cm2

O-ethyl S-(2-diisopropylaminoethyl) methylphosphonothiolate (Nerve:VX)

>480

1.25 ug/cm2

STM F1001 Chemical Test Battery*

ACETONE

>480

ACETONITRILE

87

CARBON DISULFIDE

>480

DICHLOROMETHANE

70

DIETHYLAMINE

>480

DIMETHYLFORMAMIDE

>480

ETHYL ACETATE

>480

N - HEXANE

>480

METHYL ALCOHOL

55

NITROBENZENE

>480

SODIUM HYDROXIDE

>480

SULFURIC ACID

>480

TETRACHLOROETHYLENE

>480

TETRAHYDROFURAN

>480

TOLUENE

>480

GASES

AMMONIA GAS

39

1,3 BUTADIENE GAS

>480

CHLORINE GAS

>480

ETHYLENE OXIDE GAS

81

HYDROGEN CHLORIDE GAS

>480

METHYL CHLORIDE GAS

>480

Typical Physical Properties

GRAB TENSILE STRENGTH MD* ASTM D751(LBS/N)

78 / 347

GRAB TENSILE STRENGTH CD* ASTM D751(LBS/N)

69 / 307

TEAR RESISTANCE TRAPEZOID MD*(LBS/N) METHOD DETAILS BELOW**

16.6 / 74

TEAR RESISTANCE TRAPEZOID CD*(LBS/N) METHOD DETAILS BELOW**

22.1 / 98

BALL BURST ASTM D3787 (LBS/N)

58 / 258

*MD - MACHINE DIRECTION, CD - CROSS DIRECTION

**ASTM D5587 AND ASTM D571

Shelf Life on HAZ-SUIT Chemical Garments

MIRA Safety is not aware of an accepted or universal industry standard for determining the shelf life of hazmat suits or chemical-barrier fabrics. Shelf life is typically based on the expectation of products or materials to degrade or lose effectiveness over a period of time.

When properly stored away from sunlight and in a cool, dry location not subject to temperature extremes, there’s no evidence to indicate that the MIRA Safety HAZ-Suit composite fabric loses any protective characteristics or physical properties over time.

This conclusion is based on HAZ-SUIT fabric naturally aged over twenty years. A coverall using the twenty-year-old HAZ-SUIT fabric was tested against the ASTM F1001 list of twenty-one chemicals with no breakthrough in >480 minutes.

The aged fabric was also tested for its physical properties and still meets manufacturing specifications. Based on this information, MIRA Safety considers the shelf life of its HAZ-SUIT products to be undetermined.

Chemical suits contain components made from various polymer or rubber materials for which there is no shelf life data available. Therefore, the garments may be used as long as they are deemed safe after a visual inspection, and, in the case of vapor protective (Level A) garments, after passing the ASTM F1052 pressure test. It is recommended that suits are downgraded to training use only when they no longer pass visual inspection and/or pressure testing.

It is the responsibility of the wearer to ensure that all components, including fabric, valves, visors, gloves, zippers, seams, and suit-to-component interfaces are in good working condition and provide adequate protection for the conditions and chemicals to be encountered. Any suit that does not pass the visual and/or pressure test, should be immediately removed from service.